Everything You Need

Custom Made Or Catalogue. Crushed or Pulverised.

Next Generation Solutions

Specialist Advanced Technical Products.

Uniform Consistency

Reliable, Quality Assured Products and Services.

We are the world’s largest supplier of iron ore certified reference materials, supplying every top-tier iron ore company in Australia and many specialist laboratories. We are the only manufacturer that can supply crushed or pulverised iron ore, both custom-produced and catalogue-purchased. Our expertise and product knowledge have combined to develop a unique range of specialist, technical iron ore certified reference products.

Product Range & Capability

CRUSHED OR PULVERISED

IM Standards is the world’s only current commercial manufacturer of crushed iron ore and bauxite certified reference materials. We produce our crushed CRMs with our proprietary in-house equipment and procedures.

CUSTOM OR CATALOGUE

We have the broadest range and capability of any CRM supplier in the world, offering crushed or pulverised iron ore. We manufacture custom-produced product to client specification or choose from our pre produced catalogue.

ADVANCED TECHNICAL PRODUCTS

Our expertise and product knowledge have combined to develop a unique range of specialist, technical iron ore CRMs. This range includes ISO17034 accredited materials; hygroscopic moisture corrected LOI materials; unique XRD reference material; spiked and blended materials including minor and trace analytes to certifiable concentrations (eg high Phosphorous, high Manganese, high Chlorine iron ores).

FLEXIBLE BATCH SIZE

Our flexible system allows us to produce custom batches from small to 20 tonnes.

Quality

UNIFORM HOMOGENEITY

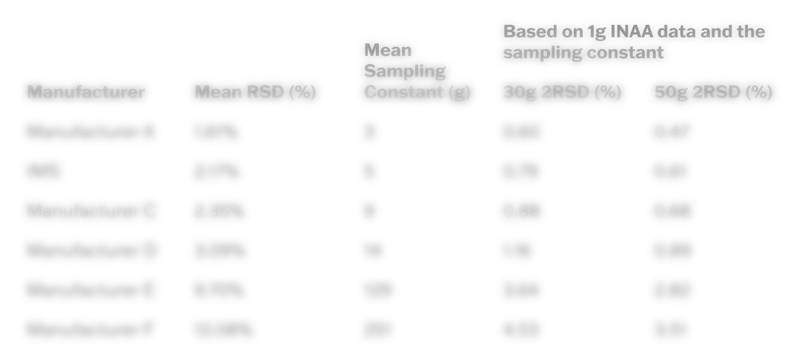

Our crushed iron ore CRMs have leading between bag homogeneity, rivalling pulverised iron ore CRM and XRF analysis method uncertainty.

QUALITY ASSURED. GLOBALLY

IM Standards was the world’s first manufacturer to secure multiple ISO accreditations, including ISO 17034 and ISO 9001. Our quality systems and processes, products and services, commitment to impartiality, continuous product improvement, training, workforce training and competency, and operational excellence are all accredited.

TRUSTED EXPERTS

Our product quality is highly regarded within the industry. We supply every major iron ore company in Australia, the world’s largest iron ore supplier. We have also made over 200 custom crushed iron ore batches for our customers.

Technical Knowledge

TECHNICAL SPECIALISTS

We built our business in iron ore and focus exclusively on the production of certified reference materials (CRMs). We have experienced, specialist staff who are globally acknowledged as leaders in their field.

PRODUCT DEVELOPMENT

We use our technical knowledge to develop specialist reference materials in response to our customer requirements in a range of commodities.

Crushed v Pulverised Iron Ore

What are the implications for laboratory quality control? Access the latest Homogeneity Assessment research report published by AusIMM.

Contact

Us

"*" indicates required fields